Debugging electronics

Intro

As a test circuit we will build our own continuity tester, using the 555 timer IC

Always check first

- do you understand the schematic (or image)

- power

- connections (soldered or breadboarded) If any dry soldering, solder bridges, any potential shorting or open PCB track issues are there?

- polarities. If any component is connect in reverse polarity, pin one of Microcontroller is soldered to pin one of the microcontroller PCB pad, etc.

- If all components are of desired value?

Understanding schematics

Breadboarding and breadboard debugging

OK, first, what's with the name....bread board? Bread, like in food?

Well yes, kind of.

This terminology goes way back in the days.

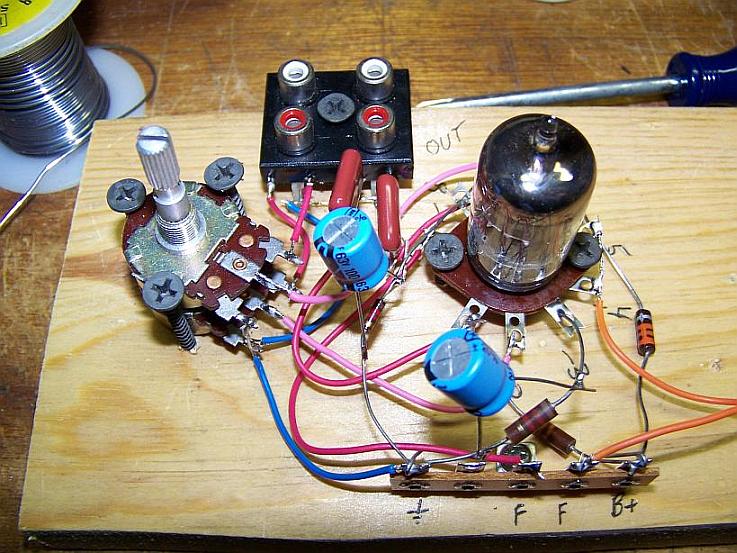

Generally, you would mount electronic components to a piece of wood (the actual "breadboard"), and do all the wiring with point-point wire and the components just hanging between the various devices.

The story goes that an engineer had an idea for a vacuum tube device late one night. Looking around the house, the only base for his prototype that he found was indeed his wife's breadboard, from the breadbox.

A video by the Make magazine people

Ok, but why do we need to breadboard?

Well, they are useful for making temporary circuits and prototyping, and they require absolutely no soldering.

Prototyping is the process of testing out an idea by creating a preliminary model from which other forms are developed or copied, and it is one of the most common uses for breadboards.

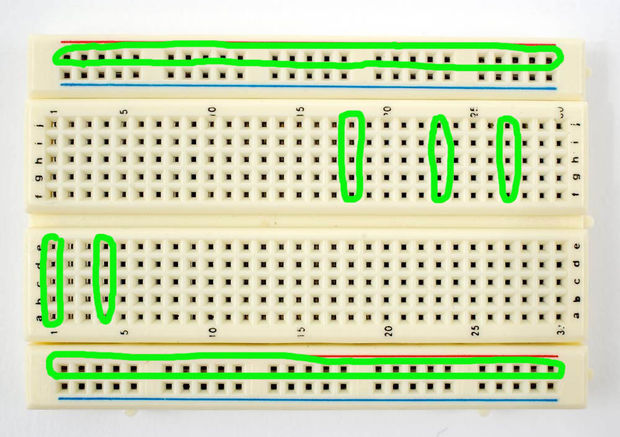

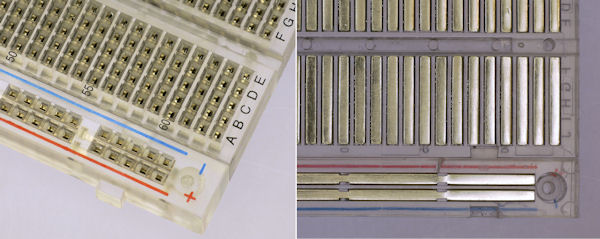

The best way to explain how a breadboard works is to take it apart and see what’s inside.

connections lines are connected like this