Swatch Making

in progress

intro

Making swatches for e-textiles.

The goal is to provide examples for simple and more advanced circuits on fabric.

The possibilities to make "soft" versions of electronic components like switches and battery holders.

preperation

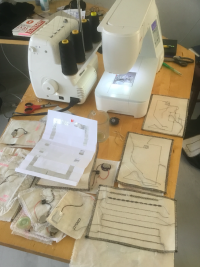

Table with tools

Putting a special spool with conductive thread inside the sewing machine.

Lock Machine

Table with swatches

tools

Machines

- Sewing machine

- lock machine

- soldering station

- scissors

- needles

- stitch undo tool

electronics

- leds

- coin cell batteries

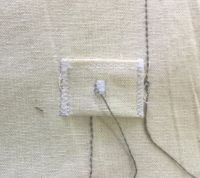

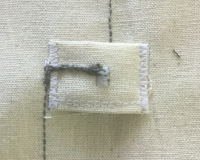

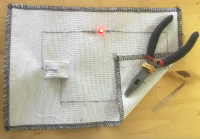

led conductive thread connection

Connecting the legs of the LED to the thread is always a bit of a problem.

There is a method making an eyelet of the leg of the LED and knotting the thread.

I trepide out a new way for me, with a small clamp:

materials

- non conductive materials

- conductive materials

- vlisofix plus aluminium foil

conductividad threads

There are many different conductive threads. Some like the Karl Grimm silver thread can be soldered. Most others, which have a plastic kernel cannot be soldered.

For using conductive thread in my Janome sewing machine I have to change the bobbin holder. I then can put the stainless steel conductive thread in the spool.

ideas

- fabric battery holder

- making a circuit

- connecting a LED

- making a textile switch

Fails

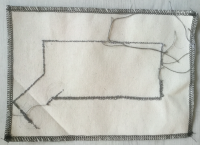

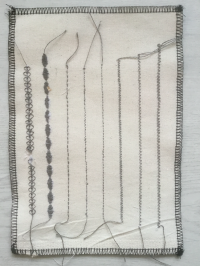

From errors you learn the most. I thought I would get a better connection by making the stitch length smaller. But then the stitching on the heavy material gets irregular.

That induced me making a swatch of the different stitch length. It turned out that the default stitch length of the machine 2.4 mm was the best. I also tried out some decorative stitches, and the zig zags.

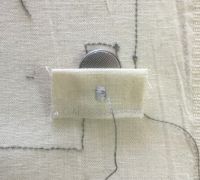

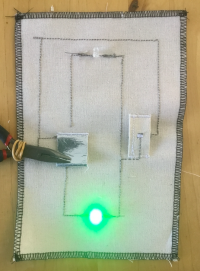

fabric battery holder

The last battery holder I made functioned, but is was also a bit inconvenient, because it was cumbersome to get the coin cell out. It was too stiff and has only one entrance.

Therefore I designed another way, a battery holder with two sides open. The base fabric holds a pattern of conductive thread and is for the larger + side of the battery. The fabric on top has a nudge of conductive material that pushes on the - side of the battery. There is of course a loop going on the outside to the minus, preventing a short cut.

nudge on top of the fabric made with a zig zag three times on top of it.

With a needle the wire has to be pushed through the material, otherwise there will be a short cut.

Placing the upper side of the fabric battery holder.

The piece is sewn on the base fabric using a zig zag, so that we don't have to fold the side again.

Connecting the wire to the wire of the circuit.

Intermediate stages

Because the sewing machine has a special spool cylinder for the conductive thread installed, the fabric battery holders have to be made later.

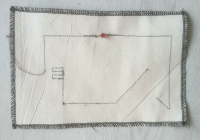

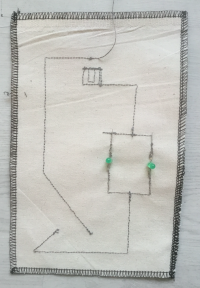

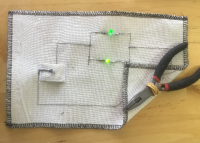

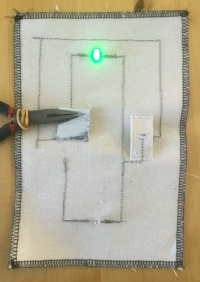

Simple circuit, with one LED. The corner fold is the switch.

Circuit with two LED's in parallel.

results

The first swatch is trying out the conductive thread, as can be seen, in plain stitching, when the stitch length is too small, the stitch gets irregular at this fabric.

Testing the simple circuit

Testing the parallel circuit.

A Fabric Switch