Difference between revisions of "Wearables: First Steps"

| (28 intermediate revisions by 2 users not shown) | |||

| Line 17: | Line 17: | ||

===fabrics=== | ===fabrics=== | ||

| + | Conductive fabrics can be used as traces and wires are used in a circuit.<br> | ||

| + | It can be cut by hand, lasercut, cut with a vinyl cutter. Lasercutting can leave smokey traces on the material and slightly melted edges. Using a vinyl cutter leaves the fabric more clean.<br> | ||

| + | Interfacing it to another fabric can be done via interfacing adhesive (such as heat n bond, that gives clean and neat results), fabric glue (it is more difficult to work with in complex shapes), sawing. | ||

[[File:Fabrics.jpeg]] | [[File:Fabrics.jpeg]] | ||

| − | |||

===thread=== | ===thread=== | ||

| + | Conductive threads are usually manufactured for anti-static, electromagnetic shielding, intelligent textiles, wearable technology, data transfer and heating purposes. Most threads are metalised with an alloy of various metals, which can include silver, copper, tin and nickel. The core is normally cotton or polyester. | ||

| + | Conductive threads are mostly non insulated and sewing them tightly to metal usually makes for a good connection, though this connection tends to loosen over time where movement occurs. One way of avoiding this is to include a squishy material, such as stretch conductive fabric underneath the stitches, or a non-conductive material, so long as it does not obstruct the electrical connection. <br> | ||

| + | |||

| + | [[File:Conductivethreadgroup.jpg]] | ||

| − | [[File: | + | ===velcro=== |

| + | Velcro is the brand name for fabric Hook and Loop fasteners. conductive velcro is highly conductive and good for making switches or connections that might need to be opened and closed. <br> | ||

| + | [[File:ADA-1324-2-684x456.jpg]] | ||

===wool=== | ===wool=== | ||

| + | Conductive wool has very fine conductive fibers (steel) mixed with normal wool, or with polyester. | ||

| + | It can be used for felting. | ||

[[File:Wool.jpg]] | [[File:Wool.jpg]] | ||

===tapes and foils=== | ===tapes and foils=== | ||

| + | Conductive tapes and foils can be used (as other conductive materials) as traces and wires are used in regular circuits. | ||

| + | the most popular and available tapes are copper (on the picture) and aluminium. They can be with an adhesive backing or without. | ||

| + | They can be shaped by cutting (by hand, by vinyl cutting). | ||

[[File:Tapes.jpg]] | [[File:Tapes.jpg]] | ||

===ink=== | ===ink=== | ||

| + | conductive inks and paints can be difficult to use on fabric, because they lack flexibility once they are dry. However they can be useful in making connection where another solution is impossible. <br> | ||

| + | |||

[[File:Ink.JPG]] | [[File:Ink.JPG]] | ||

===foam=== | ===foam=== | ||

| + | Resistive foam, ESD foam, black conductive polyurethane foam, dissipative foam | ||

| + | Comes with sensitive electronic chips and components. Available in various densities, soft or stiff. Good for pressure sensing. | ||

| + | <br> | ||

[[File:Conductive-foam.jpg]] | [[File:Conductive-foam.jpg]] | ||

| − | ===play | + | ===play doh=== |

| + | [https://squishycircuits.com/pages/dough-recipes Recipes and more HERE] | ||

| + | |||

[[File:Ff playdoh f.jpg]] | [[File:Ff playdoh f.jpg]] | ||

==non-conductive== | ==non-conductive== | ||

===adhesive interfacing=== | ===adhesive interfacing=== | ||

| + | A very good solution for interfacing conductive fabric is Heat n Bond <br> | ||

| + | Even separate pieces of conductive fabric can be glued together and if properly ironed will connect electrically (always check your connections with a multimeter and iron again if there is lack of continuity)<br> | ||

| + | [[File:Heatnbond.jpg]] | ||

| + | |||

===glues=== | ===glues=== | ||

| + | |||

| + | [http://www.vhz.nl/index.php?page=shop.product_details&flypage=flypage.tpl&product_id=180&category_id=66&option=com_virtuemart&Itemid=9 This glue is Flexible] and therefore recommended <br> | ||

| + | |||

| + | [[File:Glue.jpg]] | ||

| + | |||

===special effect pigments, etc.=== | ===special effect pigments, etc.=== | ||

| + | A great resource for purchasing special effect materials can be found [https://www.sfxc.co.uk/c HERE] | ||

====thermochromic==== | ====thermochromic==== | ||

| + | Thermochromic inks react to changes in temperature by exhibiting a colour change. | ||

| + | Can be used in combination with heating up conductive materials by inducing electric current trough the conductor. | ||

| + | [https://vimeo.com/36788169 check this video to see it working with conductive thread] | ||

| + | [[File:Termocromic.jpg]]<br> | ||

| + | [https://www.sfxc.co.uk/collections/thermochromatic-thermochromic-pigments-ink-paint/products/thermochromatic-thermochromic-colour-changing-screen-ink-for-textiles?variant=1097221981 a pack specially for dying fabric --> HERE]<br> | ||

| + | [http://www.marieledendal.se/tw-portfolio/thermochromic-textiles-activated-by-sunlight/ a phd thesis on the topic HERE] | ||

====photocromic==== | ====photocromic==== | ||

| + | |||

| + | [https://www.sfxc.co.uk/collections/photochromic-sun-powered-collection find various photocramic materials HERE] | ||

====hydrochromic==== | ====hydrochromic==== | ||

====ferrofluid==== | ====ferrofluid==== | ||

| + | |||

===fabric=== | ===fabric=== | ||

===thread=== | ===thread=== | ||

| Line 65: | Line 104: | ||

==vinyl cutter== | ==vinyl cutter== | ||

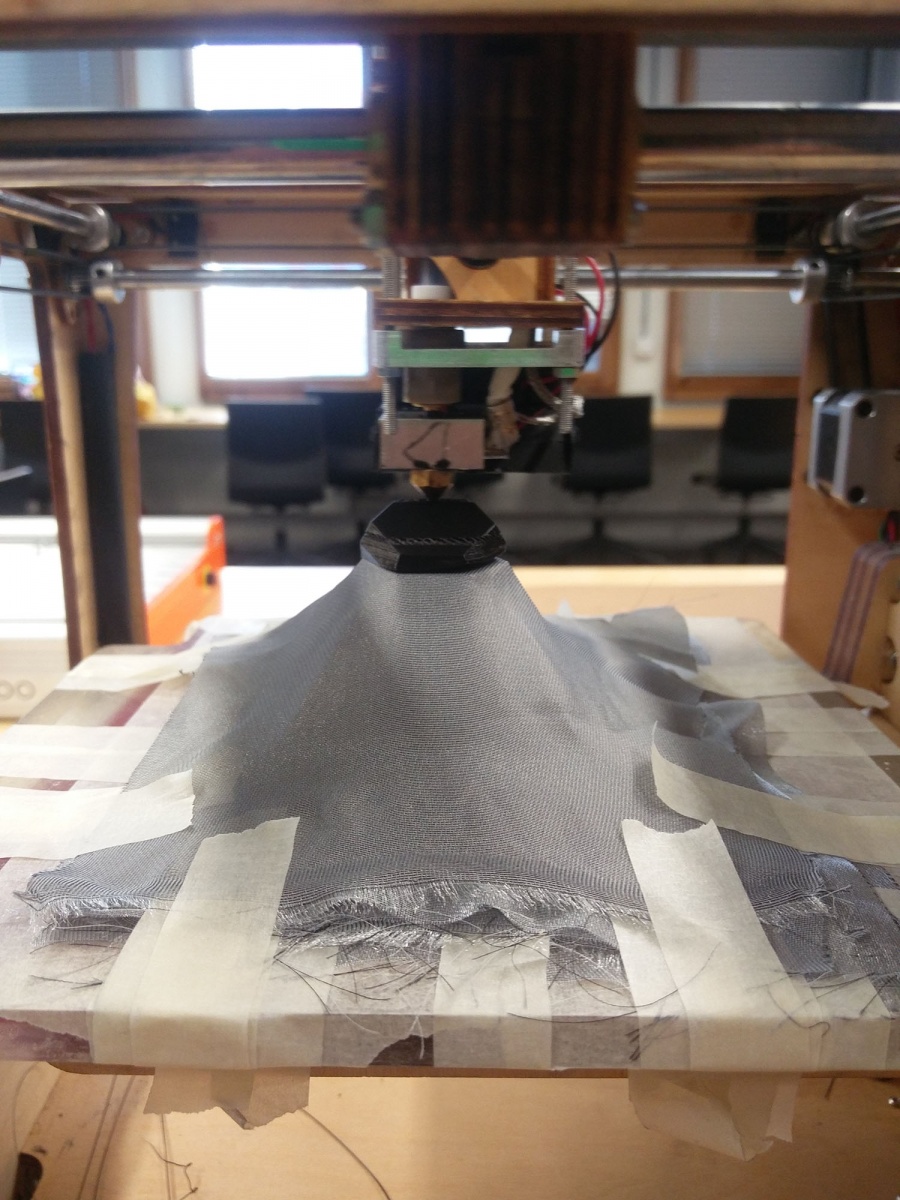

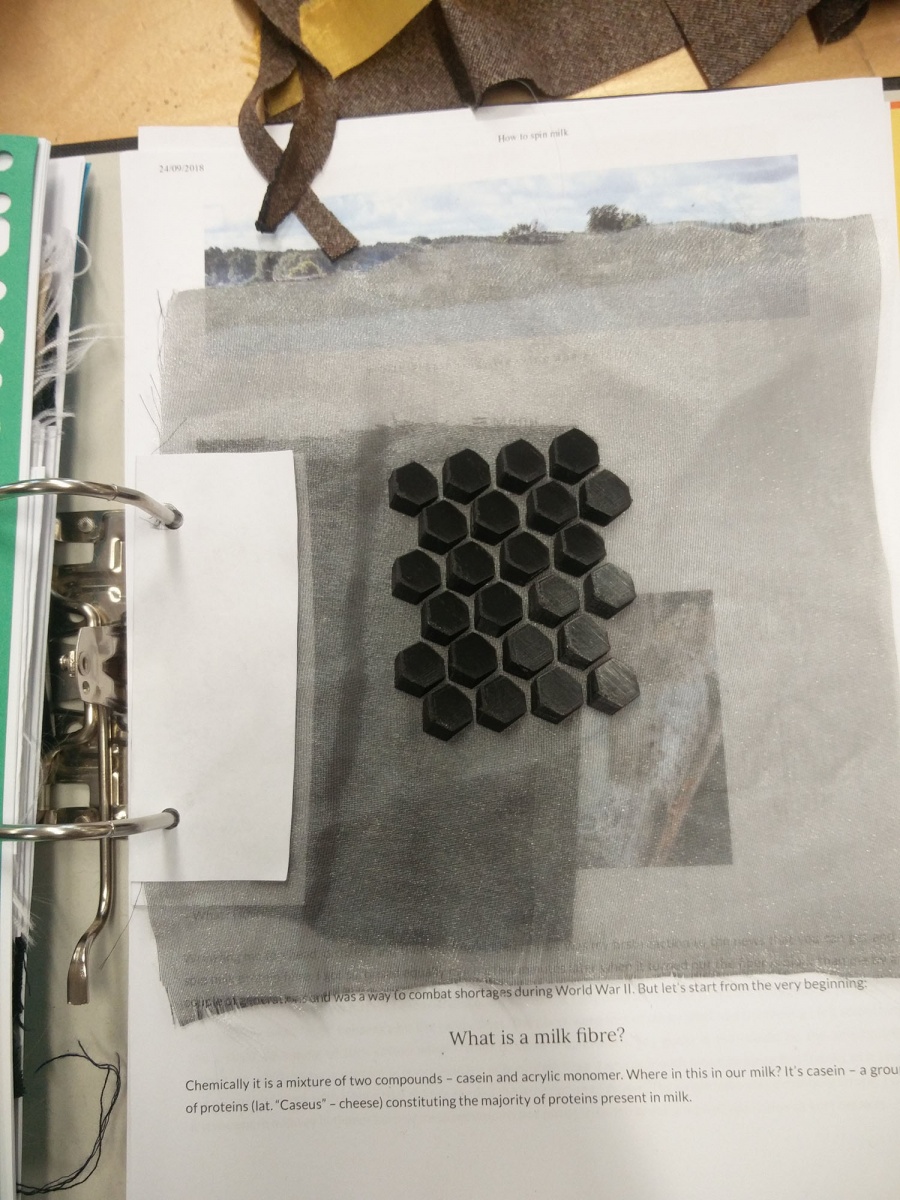

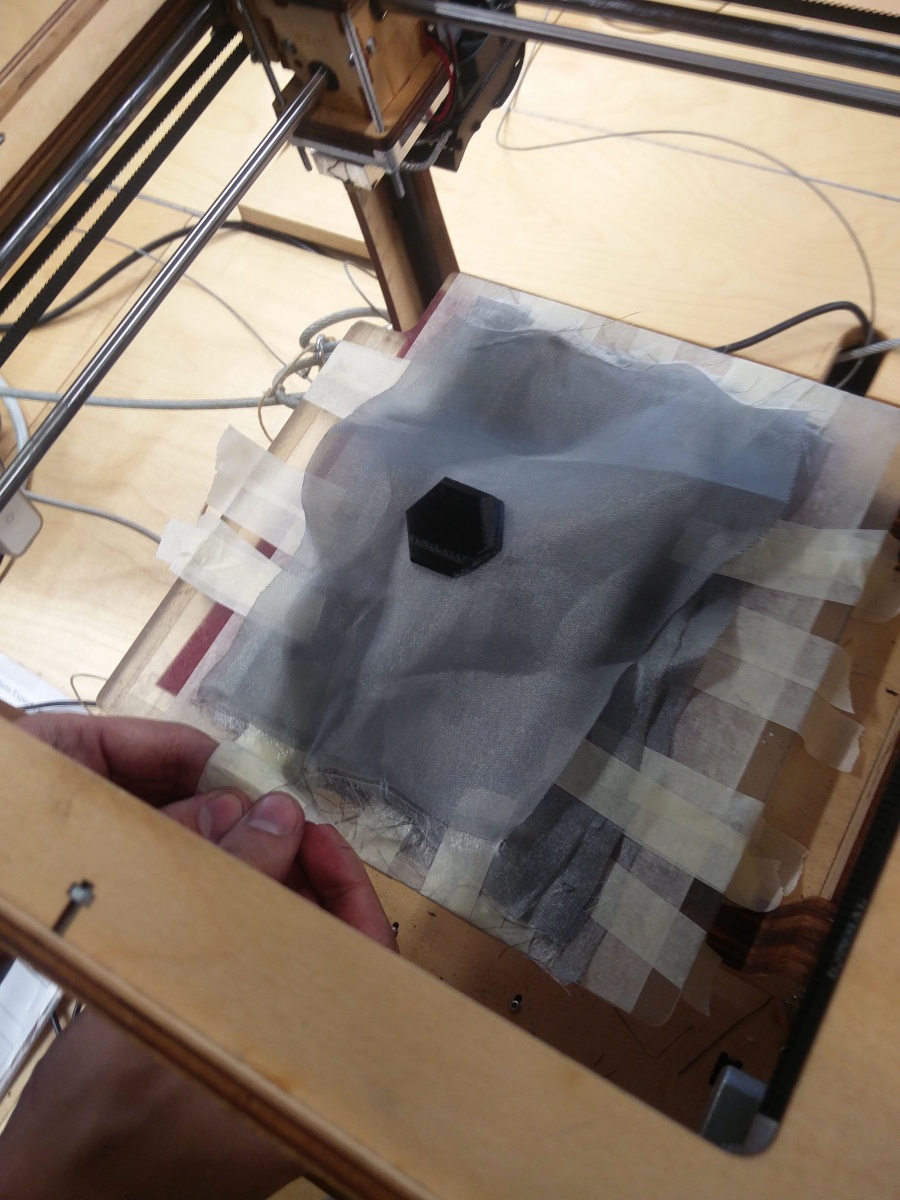

==3d printer== | ==3d printer== | ||

| − | Material Research / 3D Printing over fabric | + | Material Research / 3D Printing over fabric <br> |

| + | Sijn Zijlstra, Graphic Design | ||

[[File:IMG 20180924 153806.jpg| 900px]] | [[File:IMG 20180924 153806.jpg| 900px]] | ||

| Line 159: | Line 199: | ||

Another example of a digital sensor is an accelerometer, which sends a series of data points (speed, direction, and so on) to the Arduino. Usually digital sensors need a chip in the sensor to interpret the physical data. | Another example of a digital sensor is an accelerometer, which sends a series of data points (speed, direction, and so on) to the Arduino. Usually digital sensors need a chip in the sensor to interpret the physical data. | ||

<br> | <br> | ||

| + | === A Button is a sensor=== | ||

| + | |||

| + | We will be making the simplest sensor of them all. A button. Yes, that is a kind of a digital sensor. It is binary. On or Off. | ||

| + | <br> | ||

| + | We will follow the basic Koba tutorial, find it [https://www.kobakant.at/DIY/?p=48 here] but also feel free to explore the shapes and sizes after you get the idea. | ||

| + | |||

| + | <br> | ||

| + | Made from: stretch or non stretch fabric, stretch or non-stretch conductive fabric, fusible interfacing, foam, (metal poppers)<br> | ||

| + | Range: 2 K Ohm - 200 Ohm | ||

| + | |||

| + | [[File:FabricButton01.png | 800 px]] | ||

| + | [[File:FabricButton02.png | 800 px]] | ||

| + | |||

==Analog Sensors== | ==Analog Sensors== | ||

<br> | <br> | ||

| Line 167: | Line 220: | ||

===Bend=== | ===Bend=== | ||

| − | + | One could start by making the sticky tape sensor. | |

[https://www.instructables.com/id/Stickytape-Sensors/ Lets tape it] | [https://www.instructables.com/id/Stickytape-Sensors/ Lets tape it] | ||

[[File:12wb.jpg]] | [[File:12wb.jpg]] | ||

| − | + | This is a great bend sensor [https://www.kobakant.at/DIY/?p=20 here] and it can be used as a base to understand how it works and expand/experiment further. | |

| − | + | And it is very easy to build on our own, so we will do that. | |

| + | |||

| + | |||

| + | [[File:NeopreneBemdSensor01.png | 800 px]] | ||

| + | |||

| + | [[File:NeopreneBemdSensor02.png | 800 px]] | ||

===Tilt=== | ===Tilt=== | ||

| Line 182: | Line 240: | ||

[[File:11wb.png]] | [[File:11wb.png]] | ||

| − | |||

| − | |||

==Make your own== | ==Make your own== | ||

| Line 192: | Line 248: | ||

==analogRead our bend sensor== | ==analogRead our bend sensor== | ||

| − | === | + | ===Voltage Dividers=== |

=Resources!= | =Resources!= | ||

| Line 199: | Line 255: | ||

[https://www.instructables.com/id/Growing-Crystals-on-LEDs-and-ETextiles/ crystals ] | [https://www.instructables.com/id/Growing-Crystals-on-LEDs-and-ETextiles/ crystals ] | ||

| + | [[Category:Wearables]][[Category:Electronics]] | ||

Latest revision as of 12:57, 18 November 2022

Intro

This is an introduction to working with soft electronics.Combining and entwining circuits and fabrics. We will go trough the fundamental knowledge of electricity and how we can use it in various ways to make soft interfaces.

Materials

conductive

When we work with electronics, we obviously need electricity to power our work, so a crucial component of our work are conductive materials, or conductors. Conductors are substances that allow the flow of electrical current through them. The most common and well-known conductors of electrical current are metals. Both conductivity and resistivity are properties of conductors. As we focus on wearables, it will be in our interest to move further than using simply wire, that is most commonly used in electrical circuits and explore other conductive materials.

conductive and resisitive

Simplified explanation: they are opposites!

Resistivity - the amount of opposition to electrical flow

Conductivity - how easy it is for an electrical flow

fabrics

Conductive fabrics can be used as traces and wires are used in a circuit.

It can be cut by hand, lasercut, cut with a vinyl cutter. Lasercutting can leave smokey traces on the material and slightly melted edges. Using a vinyl cutter leaves the fabric more clean.

Interfacing it to another fabric can be done via interfacing adhesive (such as heat n bond, that gives clean and neat results), fabric glue (it is more difficult to work with in complex shapes), sawing.

thread

Conductive threads are usually manufactured for anti-static, electromagnetic shielding, intelligent textiles, wearable technology, data transfer and heating purposes. Most threads are metalised with an alloy of various metals, which can include silver, copper, tin and nickel. The core is normally cotton or polyester.

Conductive threads are mostly non insulated and sewing them tightly to metal usually makes for a good connection, though this connection tends to loosen over time where movement occurs. One way of avoiding this is to include a squishy material, such as stretch conductive fabric underneath the stitches, or a non-conductive material, so long as it does not obstruct the electrical connection.

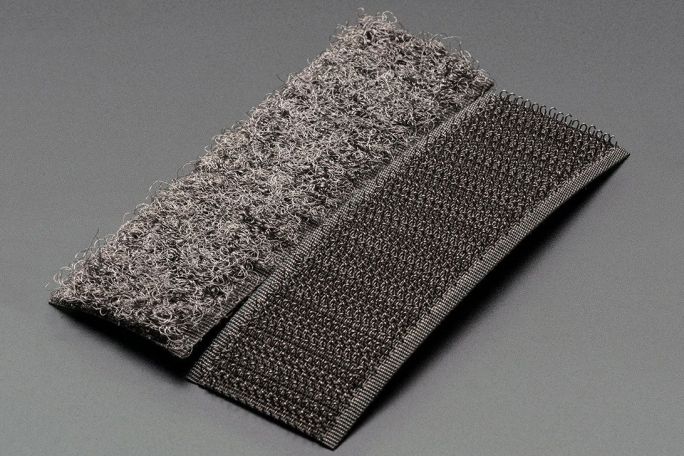

velcro

Velcro is the brand name for fabric Hook and Loop fasteners. conductive velcro is highly conductive and good for making switches or connections that might need to be opened and closed.

wool

Conductive wool has very fine conductive fibers (steel) mixed with normal wool, or with polyester. It can be used for felting.

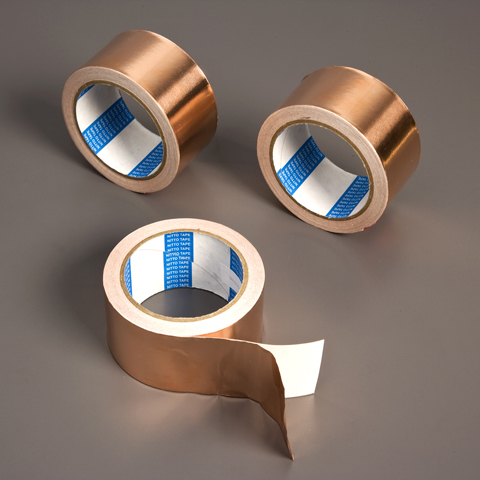

tapes and foils

Conductive tapes and foils can be used (as other conductive materials) as traces and wires are used in regular circuits. the most popular and available tapes are copper (on the picture) and aluminium. They can be with an adhesive backing or without. They can be shaped by cutting (by hand, by vinyl cutting).

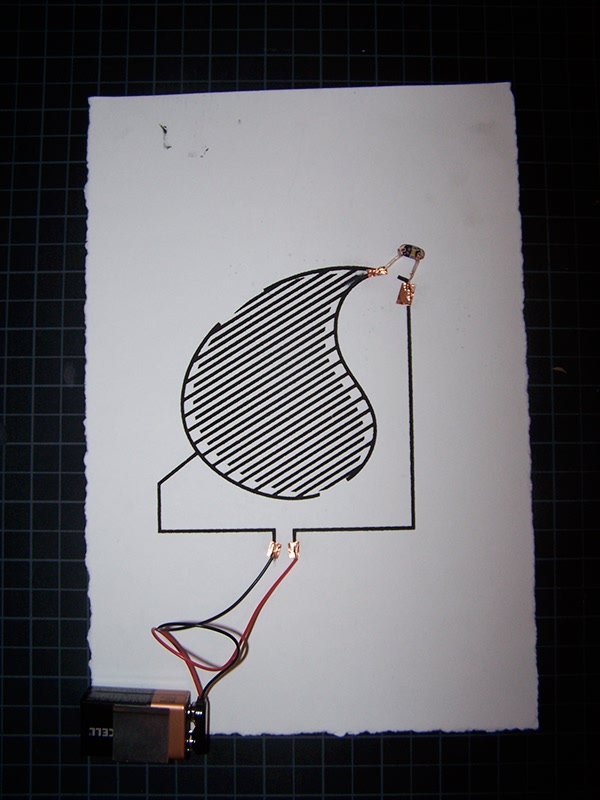

ink

conductive inks and paints can be difficult to use on fabric, because they lack flexibility once they are dry. However they can be useful in making connection where another solution is impossible.

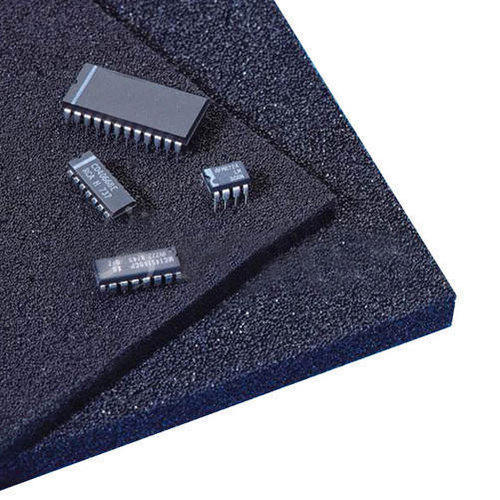

foam

Resistive foam, ESD foam, black conductive polyurethane foam, dissipative foam

Comes with sensitive electronic chips and components. Available in various densities, soft or stiff. Good for pressure sensing.

play doh

non-conductive

adhesive interfacing

A very good solution for interfacing conductive fabric is Heat n Bond

Even separate pieces of conductive fabric can be glued together and if properly ironed will connect electrically (always check your connections with a multimeter and iron again if there is lack of continuity)

glues

This glue is Flexible and therefore recommended

special effect pigments, etc.

A great resource for purchasing special effect materials can be found HERE

thermochromic

Thermochromic inks react to changes in temperature by exhibiting a colour change.

Can be used in combination with heating up conductive materials by inducing electric current trough the conductor.

check this video to see it working with conductive thread

a pack specially for dying fabric --> HERE

a phd thesis on the topic HERE

photocromic

find various photocramic materials HERE

hydrochromic

ferrofluid

fabric

thread

Tools

sewing machine

multimeter

pliers

scissors

lasercutter

vinyl cutter

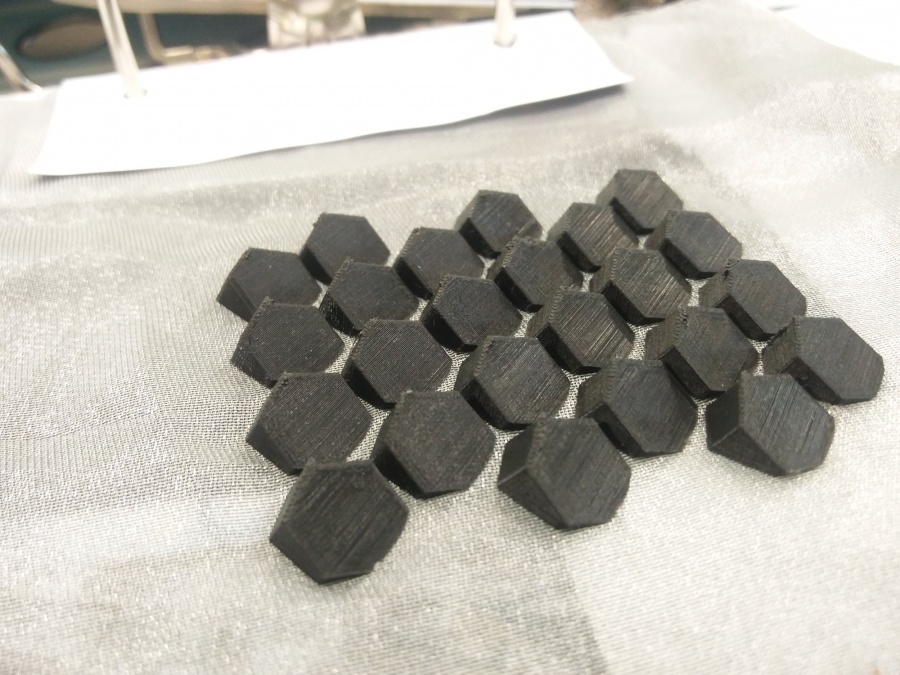

3d printer

Material Research / 3D Printing over fabric

Sijn Zijlstra, Graphic Design

breadboard

microcontroller

arduino

flora

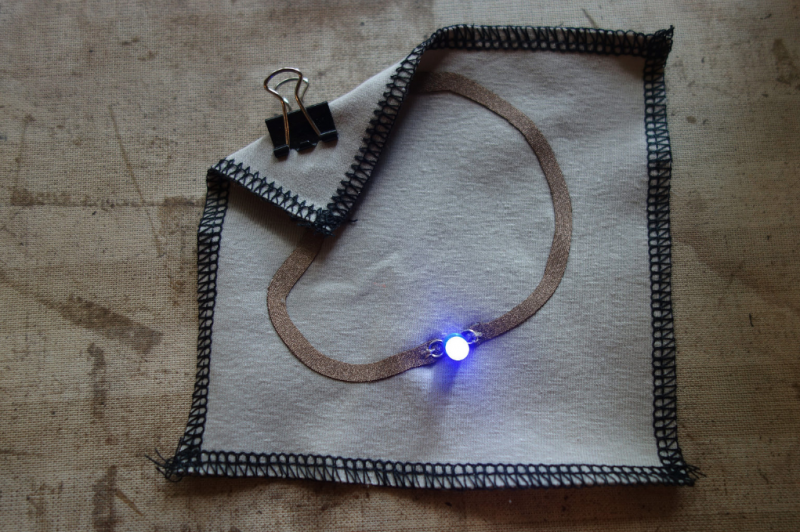

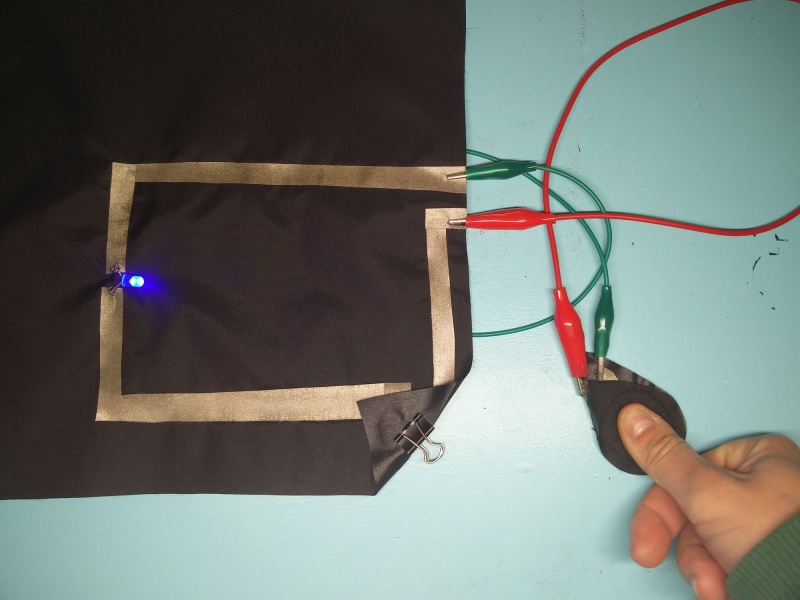

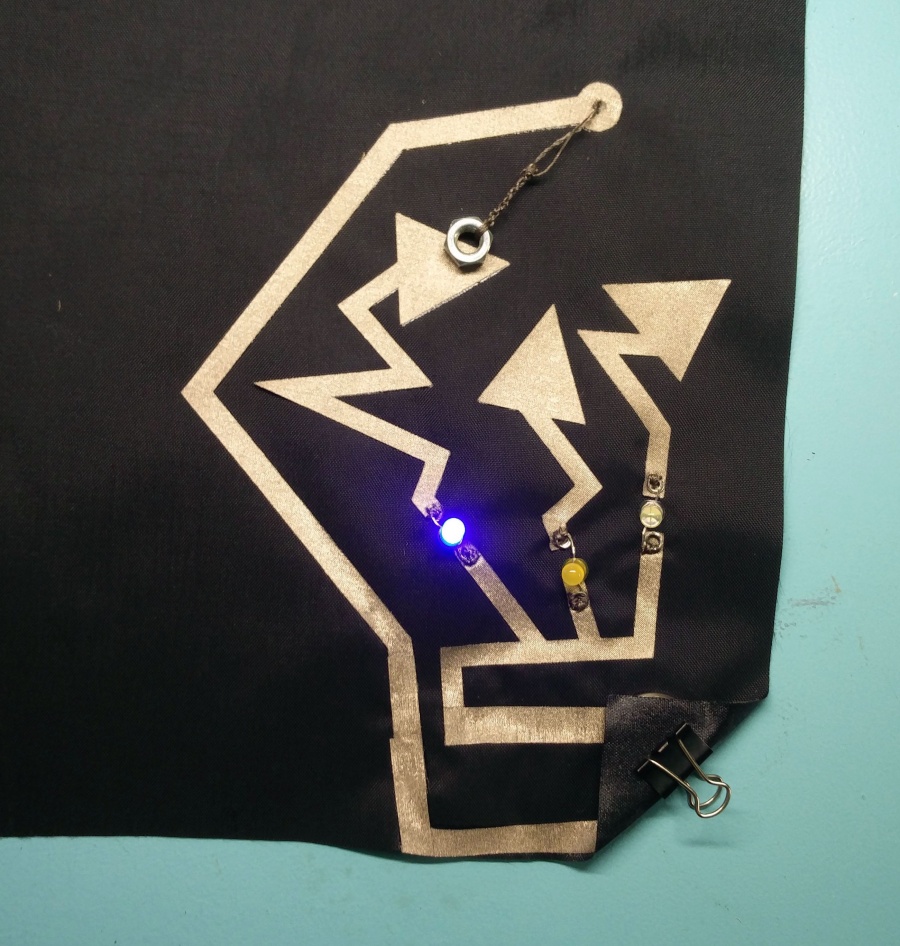

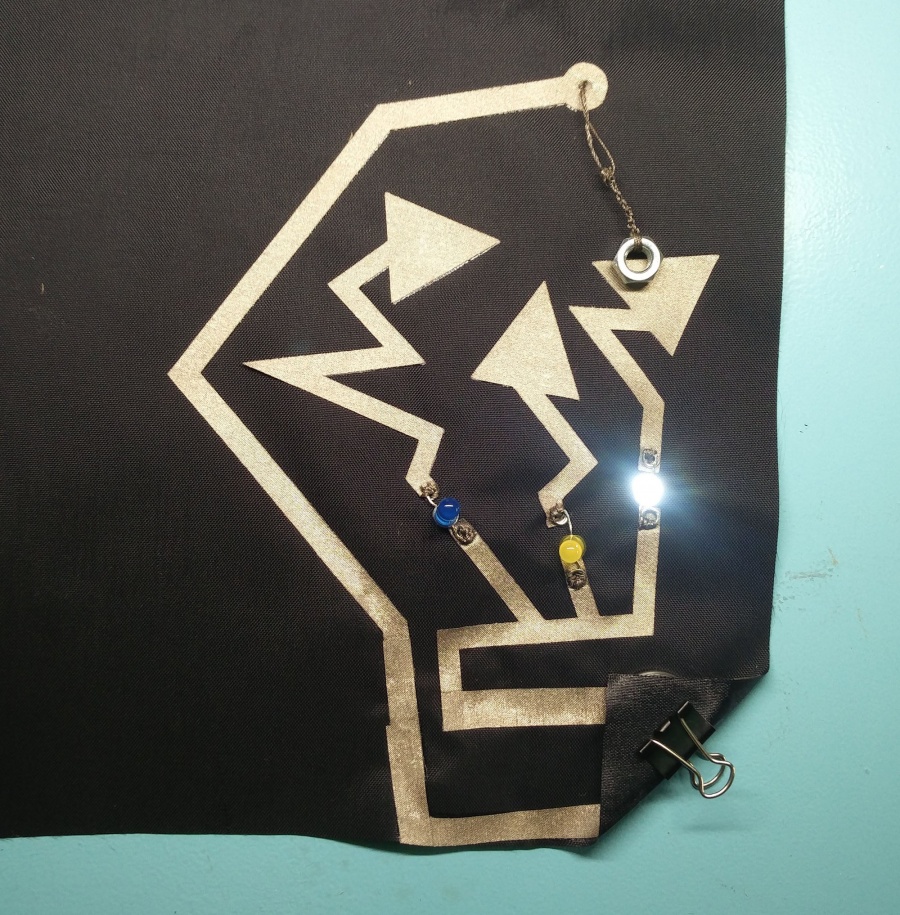

Hello wolrd: Soft circuit

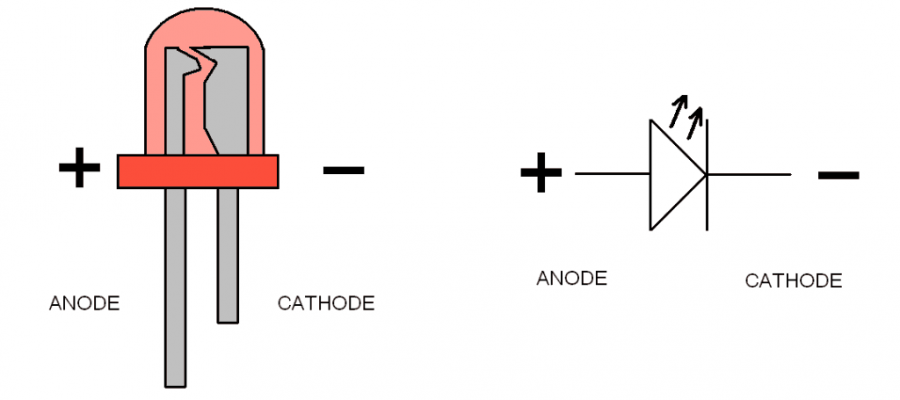

For the hello world we will use an led as an output.

A light-emitting diode (LED) is a two-lead semiconductor light source. When a suitable voltage is applied to the leads, electrons are able to recombine with electron holes within the device, releasing energy in the form of photons. (https://en.wikipedia.org/wiki/Light-emitting_diode)

There are two things we have to take care when using LED.

– LED has polarity. Make sure to connect LED in correct direction.

You can tell the direction as the positive side usually has a longer leg, or a smaller triangle lead in the epoxy lens. Or a dent in the epoxy on the negative side.

How much voltage and current does LEDs require to light up?

It depends on the LED and you will need to check its datasheet to know exact specification. The voltage you need is called “(forward) voltage drop” and the current required is called “forward current”. Most of the normal (not super bright) LEDs light up somewhere around 2-2.5v and require 20-30mA.

How much voltage and current does LEDs require to light up?

It depends on the LED and you will need to check its datasheet to know exact specification. The voltage you need is called “(forward) voltage drop” and the current required is called “forward current”. Most of the normal (not super bright) LEDs light up somewhere around 2-2.5v and require 20-30mA.

– You will need to limit the current to suitable range. you can read here “why?” >> To limit the current, you need to add resisters in your circuit. You can calculate it yourself using Ohm’s law, or use online calculators like this one >> http://led.linear1.org/1led.wiz

simple

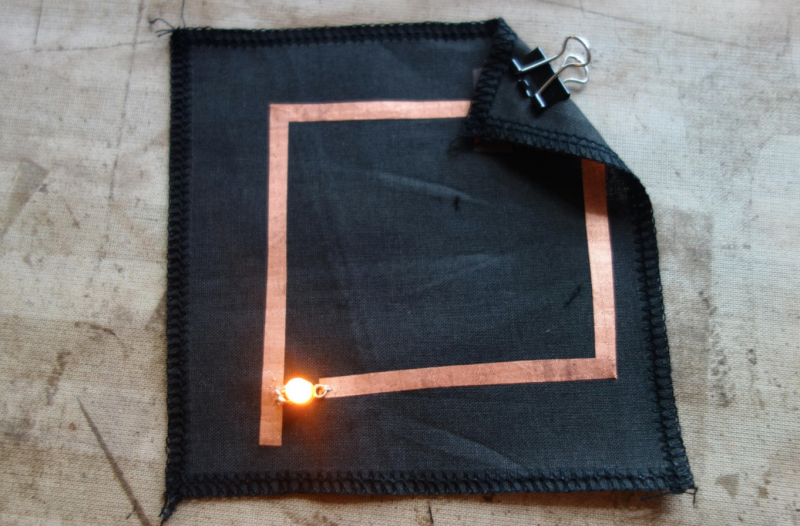

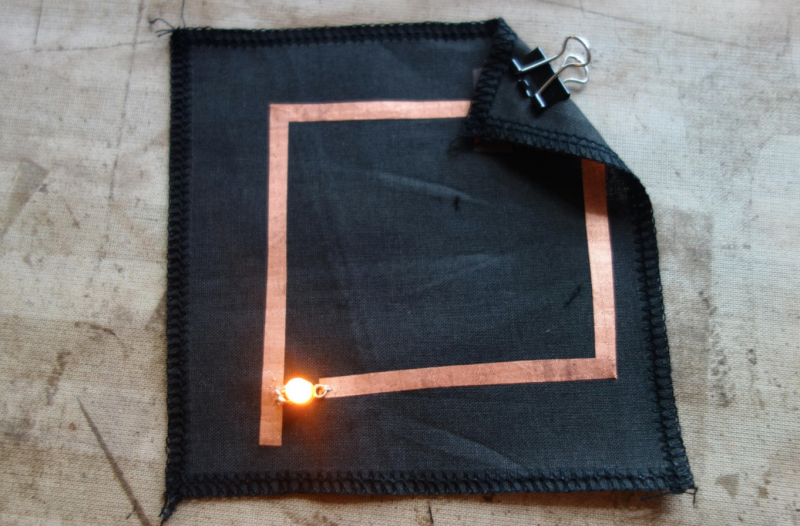

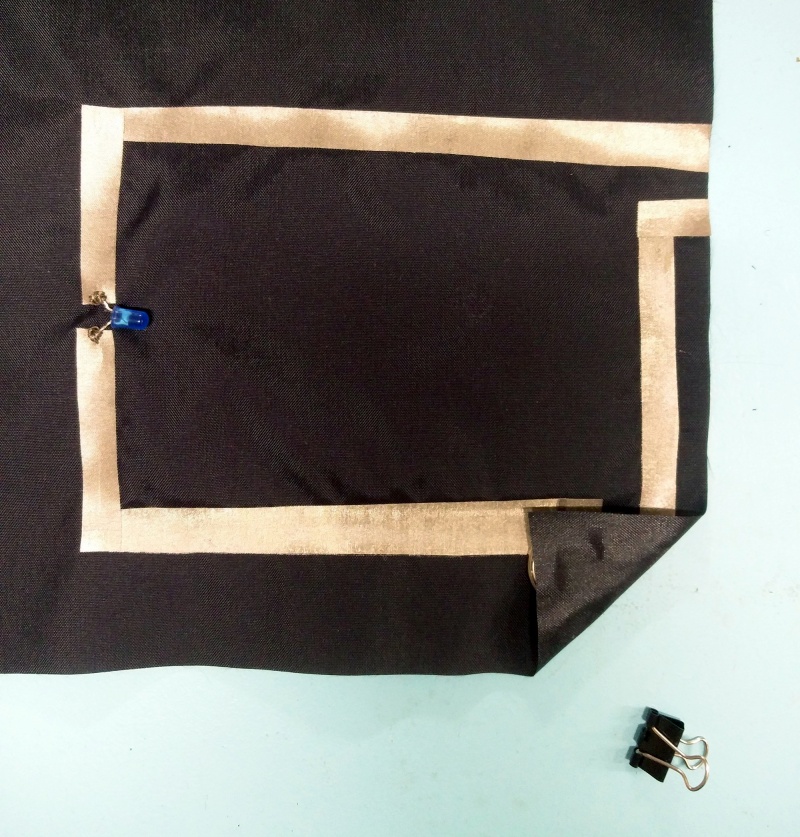

Lets s start my making the hello world of soft and any kind of circuitry:) And use the led we talked so much about.

Cut conductive fabric that has fusible interfacing on one side. peel off the backing paper and place it on base fabric. Make sure the iron is set to synthetic. Most conductive fabric is delicate. And you do also rist the glue from the interfacing glue to appear of the front.

You can cut each side or fold to make corners. In both cases we need to check if all connections are right. We will use the continuity setting.

We make a rectangular shape and leave both sides open. On one side we will clamp the battery, and on the other: sew the led.

Use pliers ( best rounf ones) to bend the led legs into hooks. That way it will be easy to sew.

Then we will use a clip to hold the battery in place.

Many options are possible of course. Both in materials and design. But we have to get started,

You can also use conductive thread to make the circuit.

with button

But be fore we start. Lets make the push button.

Here is the Kobakant push button. we have this kit and we have also some vinyl cut fabric.

Conductivity

Resistance

Sensors

Digital Sensors

Digital sensors are the sensors that gives 2 state (on/off, 5V/0V). You will connect them to digital Pins and set it as INPUT.

Digital data consists exclusively of 0s and 1s .

For example, consider a push button switch. This is one of the simplest forms of sensors. It has two discrete values. It is on, or it is off. Other 'discrete' sensors might provide you with a binary value.

Another example of a digital sensor is an accelerometer, which sends a series of data points (speed, direction, and so on) to the Arduino. Usually digital sensors need a chip in the sensor to interpret the physical data.

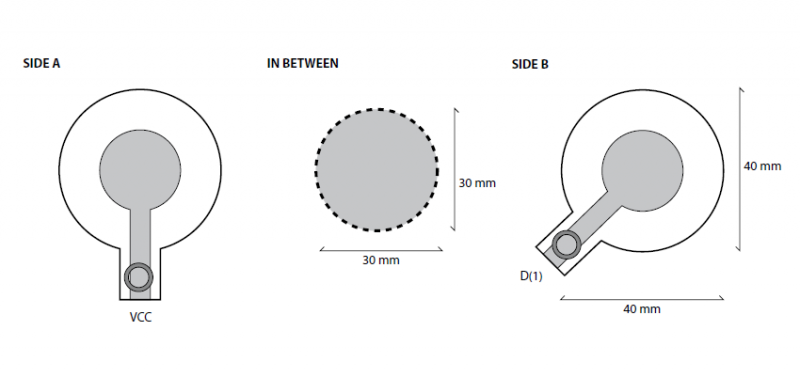

A Button is a sensor

We will be making the simplest sensor of them all. A button. Yes, that is a kind of a digital sensor. It is binary. On or Off.

We will follow the basic Koba tutorial, find it here but also feel free to explore the shapes and sizes after you get the idea.

Made from: stretch or non stretch fabric, stretch or non-stretch conductive fabric, fusible interfacing, foam, (metal poppers)

Range: 2 K Ohm - 200 Ohm

Analog Sensors

Analog sensors on the other hand, gives range. You connect this types of Analog sensors to Analog Input pins which is measuring the incoming voltage between 0V-5V*. Arduino converts this incoming voltage into the number between 0-1023.

Analog data is transmitted as a continuous signal, almost like a wave. In other words, an analog sensor doesn’t send a burst of 1s and 0s like digital sensors do; instead, the sensor modulates a continuous signal to transmit data.

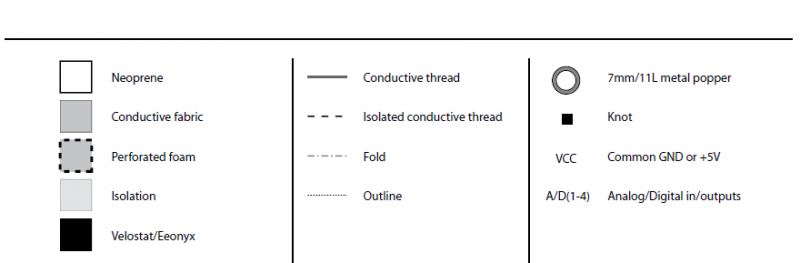

Bend

One could start by making the sticky tape sensor. Lets tape it

This is a great bend sensor here and it can be used as a base to understand how it works and expand/experiment further. And it is very easy to build on our own, so we will do that.

Tilt

Make your own

Microcontrolling it

digitalRead our button

analogRead our bend sensor

Voltage Dividers

Resources!

Biggest resource for everything wearable related BIG UP for Kobakant