Textile Actuators

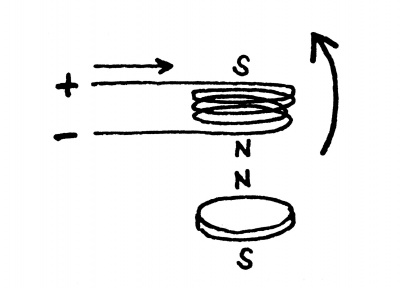

Electromagnetic Coil

1. Flapping Wings

{{#ev:youtube|https://www.youtube.com/watch?time_continue=2&v=jrPeOXibGUk&feature=emb_logo}}

This video demonstrates how the combination of an electromagnetic coil and a permanent magnet can be used to create a “flapping” movement……

How it works:

Electromagnetic coils are made of enameled wire coated with a very thin layer of insulation.

When the current flowing through the coil, it generates an electromagnetic field.

In this case, either attracts or repels a permanent magnet to create movements.

Changing the direction of the turns of a coil and the polarity of the DC power source can change the polarity of the magnet.

How to make it:

you will need:

Materials:

cotton fabric, silk fabric, cotton thread, neodymium magnet (1cm diameter, 2mm high, axially magnetized), enameled copper wire (0.01mm diameter), copper tape, solder

Tools:

sewing needle, pinking shears, scissors, soldering iron, tweezers, cutter knife, 7mm diameter shaft (end of pen or round tool)

Follow the [|Step-by-Step Instructions]

2. Soft Speaker

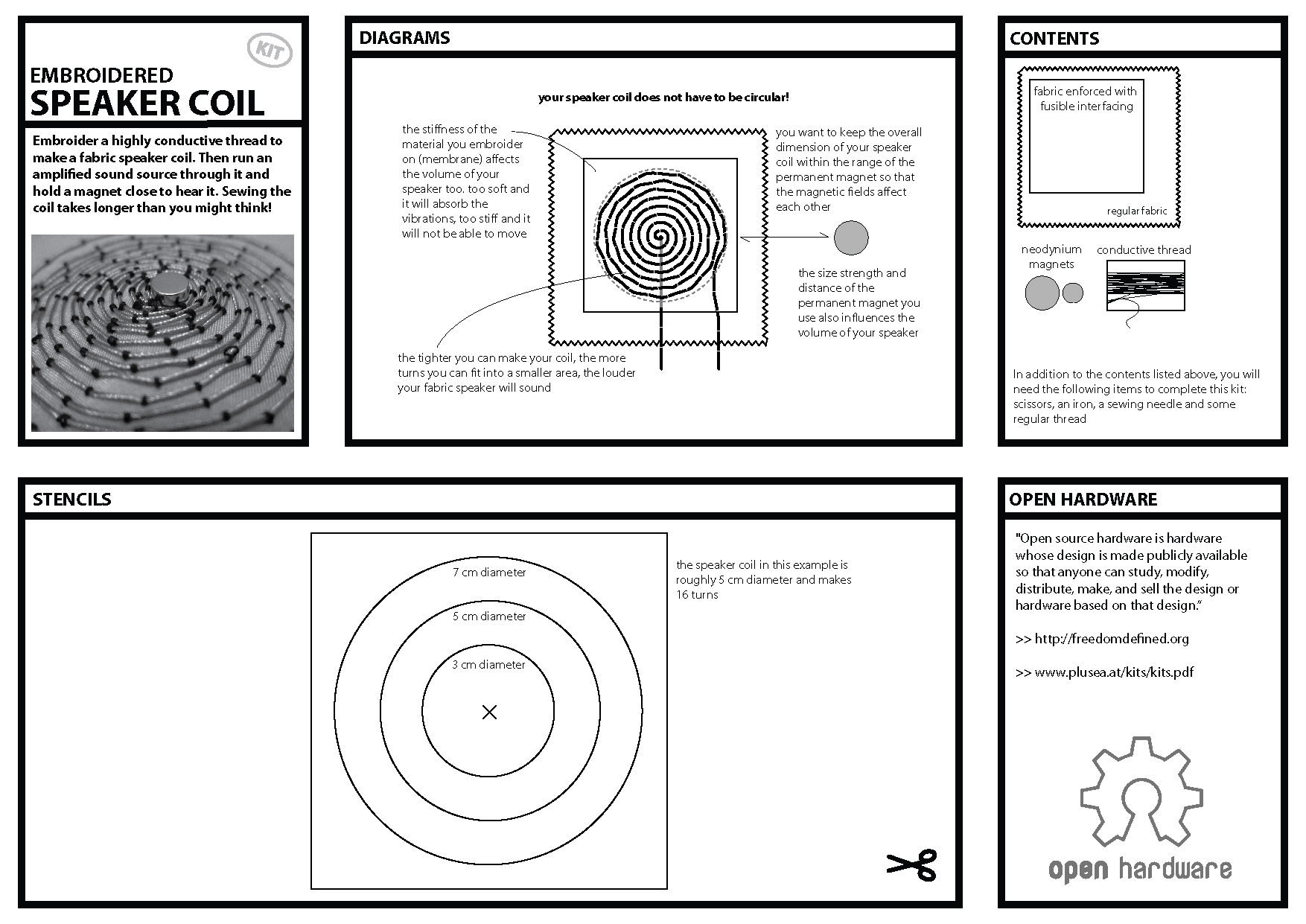

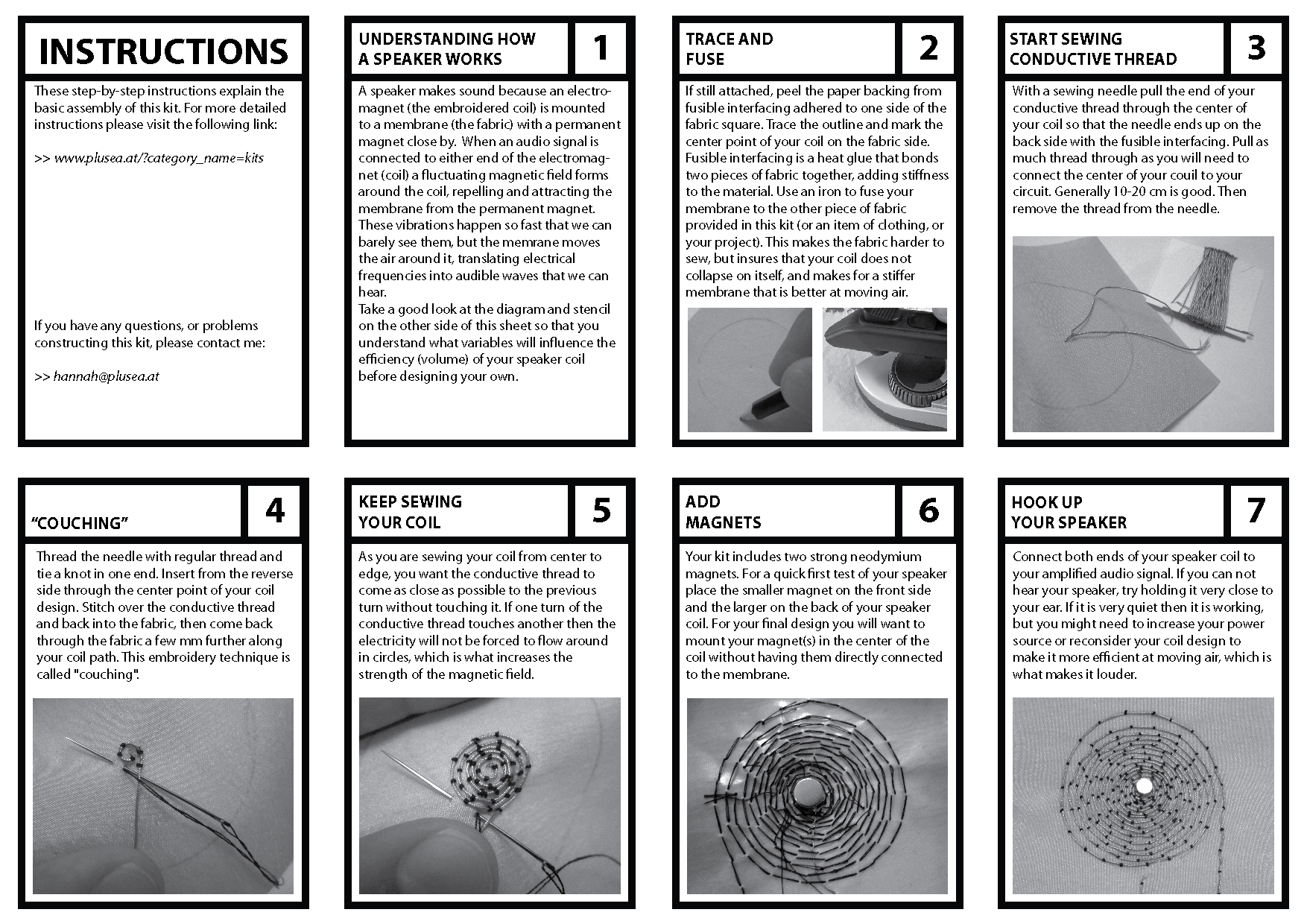

UNDERSTANDING HOW A SPEAKER WORKS

A speaker makes sound because an electromagnet (the embroidered coil) is mounted to a membrane (the fabric) with a permanent magnet close by.

When an audio signal is connected to either end of the electromagnet (coil) a fluctuating magnetic field forms around the coil,

repelling and attracting the membrane from the permanent magnet. These vibrations happen so fast that we can barely see them,

but the membrane moves the air around it, translating electrical frequencies into audible waves that we can hear.

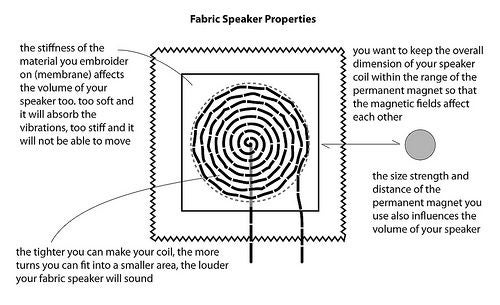

Take a good look at the diagram and stencil on the other side of this sheet so that you understand what variables will influence

the efficiency (volume) of your speaker coil before designing your own.

1.Embroidered Fabric Speaker

{{#ev:youtube|https://www.youtube.com/watch?time_continue=2&v=sJDrZaG-K2M&feature=emb_logo}}

How to make it:

Take a good look at the diagram and stencil on the other side of this sheet so that you understand what variables will influence the efficiency (volume) of your speaker coil before designing your own.

we have [|Embroidered speaker kits] at the interaction station.

After we finish the construction of the soft speaker,

We now need an audio amplifier to amplifier the audio signal in order to play it via the soft speaker.

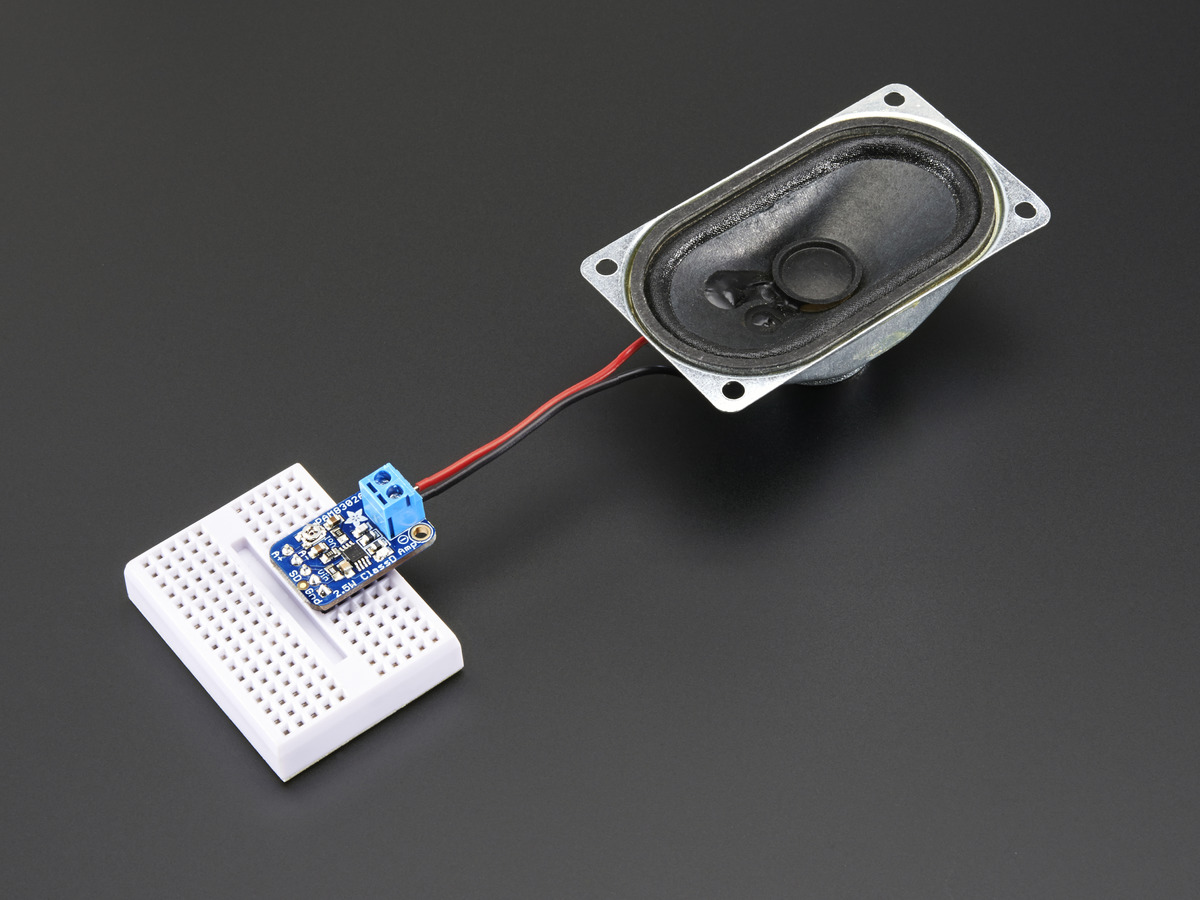

[Audio Amplifier](we use this amplifier from adafruit)

connect the two-wire from the soft speaker the same as a normal speaker(can be connected in any direction):

and power the amplifier from 2.0V-5.5VDC to VIN and GND pin.

connect a mono audio jack to A- A+ pin.

and it is done!

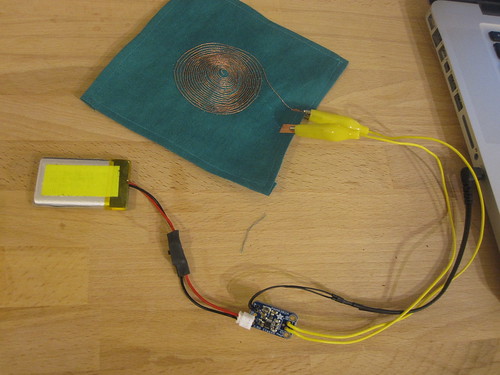

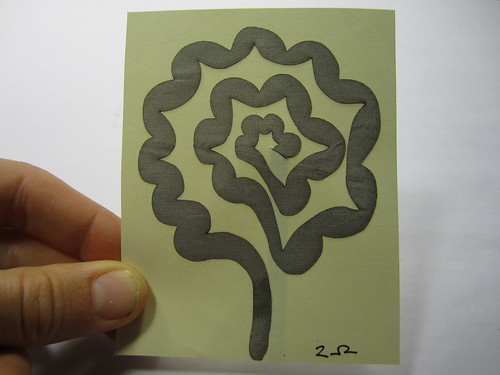

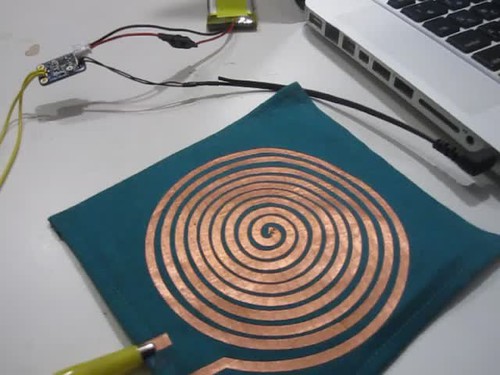

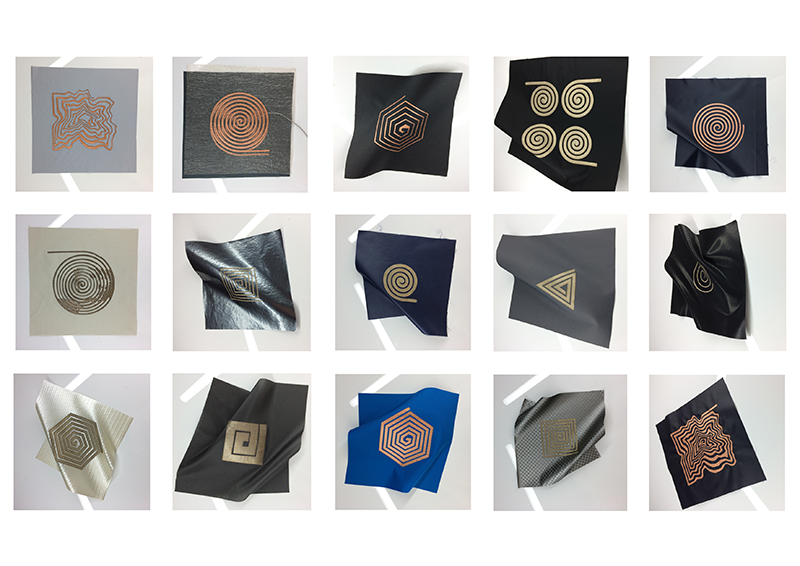

2.Conductive Fabric Speaker

You can also make a soft speaker with other techniques:

1.Conductive fabric lasercut and fused to paper.

2. Conductive fabric lasercut and fused to canvas.

3.copper conductive fabric cut with Vinyl cutter, then fused onto fabric with fusible interfacing.

How to make it:

Follow [Fabric Speaker Step by step guide:]

Example of works:

1. Draping Sound-EJTech

{{#ev:vimeo|https://vimeo.com/348487065}}

2. 48 channel textile sound system

{{#ev:vimeo|https://vimeo.com/364045010}}

3.Sound_Embroidery

{{#ev:vimeo|https://vimeo.com/184542929}}

4. sftspkr_No.1 - Space Oddity Sound System {{#ev:vimeo|https://vimeo.com/107454046}}

5.Soft Sound {{#ev:vimeo|https://vimeo.com/205792057}}

Nitinol Wire

1. Musle wire

2. Memory Wire

{{#ev:youtube|https://www.youtube.com/watch?v=F8L_etiBGMc&feature=emb_rel_end}}

Nitinol and Felt (test 4): the "jellyfish"

{{#ev:youtube|https://www.youtube.com/watch?v=MGMH-R7s2oM}}

The wire was pre-annealed to be plastic. Raw Nitinol is usually superelastic.

If you want shape memory wire then you must anneal the raw wire for 15 minutes by 500°C.

Then it lose its superelasticity and becomes shape memory wire.

{{#ev:vimeo|https://vimeo.com/33861667}}

Flexinol wire system

Muscle wire, also known as flexinol was the particular smart material that was chosen to be investigated for this project.

Flexinol is a shape memory alloy actuator wire. Made of nickel-titanium these small diameter wires contract (typically 2% to 5% of their length) like muscles when electrically driven or heated.

Although, the contraction might seem small, it is accompanied by such force that it can easily be applied through levers and linkages to achieve much larger movements.

{{#ev:youtube|https://www.youtube.com/watch?v=DW4WaTmoZ3c}}

{{#ev:youtube|https://www.youtube.com/watch?time_continue=1&v=4JQl8_D-370&feature=emb_logo}}