Difference between revisions of "E-waste"

| Line 118: | Line 118: | ||

==Making it work / building the circuit == | ==Making it work / building the circuit == | ||

| − | [[File:Joule.jpg]] | + | [[File:Joule.jpg | 700 px]] |

Revision as of 23:29, 18 November 2021

some quotes on being e-wasted

Electronic waste (e-waste) is a term that is used loosely to refer to obsolete, broken, or irreparable electronic devices like televisions, computer central processing units (CPUs), computer monitors (flat screen and cathode ray tubes), laptops, printers, scanners, and associated wiring.

From 'Mining electronic waste for precious metals' Professor John Blacker and colleagues around the world are finding ways to reclaim valuable materials from discarded electronics. University of Leeds

This e-waste usually arrives at landfill sites where it is processed by hand by e-waste workers who extract the materials they can sell on, such as copper and silicon. Without access to sophisticated recycling technologies, the workers have no option but to do this by hand: stripping cables, hammering out components, or using chemicals or heat. It creates dangerous working conditions, and the money the workers make is small.

Professor John Blacker of the University of Leeds explains: “To separate the materials, e-waste workers have to burn components in open pots, or dip them in vats of acid. That results in toxic bi-products and smoke — and it’s rare that any protective equipment is ever provided. The acids and bi-products sometimes leach into soil and groundwater, which has a wider ecological impact on the whole community.”

From Determining Metal Content in Waste Printed Circuit Boards and their Electronic Components Article in Journal of Sustainable Development of Energy Water and Environment Systems · March 2020

Waste Electrical and Electronic Equipment (WEEE) is one of the fastest growing waste types [1]: with three times higher growth than municipal solid waste [2]. Electrical and Electronic Equipment (EEE) industry consumes 30% of annual silver (Ag) production (6,000 t), 12% of gold (Au) (300 t), 15% of bismuth (Bi) (900 t), 19% of cobalt (Co) (11,000 t), 30% of copper (Cu) (4,500,000 t), 14% of palladium (Pd) (33 t), 50% of antimony (Sb) (65,000 t) and 33% of tin (Sn) (90,000 t) manufacture [3]. A large quantity of WEEE is traded illegally, and in 2011 only the legal trade of WEEE was estimated at 52 billion USD [4]. Common discarding of waste in landfills or open spaces, is highly damaging to the environment [5]. Despite the efforts to limit illegal waste streams by a legal framework, approximately 70% of WEEE in the world is discarded in China.

Some common precious metals in electronics

Au Gold is the easiest precious metal to recognize because of its unique yellow color. Gold is popular because of its color, malleability, and conductivity. Uses: Jewelry, electronics, radiation shielding, thermal insulation Major Sources: South Africa, United States, China, Australia

Ag Silver is a popular precious metal for jewelry, but its value extends well beyond beauty. It has the highest electrical and thermal conductivity of all the elements and has the lowest contact resistance. Uses: Jewelry, coins, batteries, electronics, dentistry, antimicrobial agents, photography Major Sources: Peru, Mexico, Chile, China

Ir Iridium is one of the densest metals. It also has one of the highest melting points and is the most corrosion-resistant element. Uses: Pen nibs, watches, jewelry, compasses, electronics, medicine, automotive industry Major Source: South Africa

The Platinum Group Metals are a group of six rare metals: platinum, palladium, rhodium, ruthenium, iridium and osmium. Resistance to corrosion and tarnishing, combined with mechanical strength and hardness, make the Platinum Group Metals suitable for highly demanding applications

Pd Palladium Uses: Found in nearly all electronic devices, palladium is key in the manufacture of computer chips and circuits. MLCCs and hybrid integrated circuits (HIC) contain palladium, as do thermocouples, contacts, circuit board frames, electrothermal fuses and electroplating. The largest area of palladium use in the electronics sector is in multi-layer ceramic (chip) capacitors (MLCC) Palladium is often preferred to gold plating because less material weight is needed to achieve the same thickness. Palladium-silver alloys are used to make electrodes. Major Source: Russia, South Africa

Pt Platinum Uses: in thermocouples, platinum is also used in contacts, fine resistance wires and permanent magnets. Platinum is ideally suited to corrosive or high-voltage conditions. In alloy form it is used as a magnetic coating for hard disk drives, optical storage systems and as a fabrication material in making high-grade glass for electroluminescent diodes. Major Source: South Africa

Base metals

Base metals are any nonferrous (they contain no iron) metals that are neither precious metals nor noble metals. The most common base metals are copper, lead, nickel, tin, aluminum, and zinc. Applications Base metals are used in a wide variety of applications. Copper Cu is commonly used in electrical wiring because of its high ductility and conductivity. Its high ductility means it easily can be stretched thin without losing strength.

Lead Pb has proven to be a reliable source for batteries, and nickel often is used to strengthen and harden metal alloys, including stainless steel. Base metals also are used frequently to coat other metals. For example, zinc is used to coat galvanized steel.

Aluminum Al is the third most abundant element in the earth's crust (trailing only oxygen and silicon) and it does the highest volume of trading on the London Metal Exchange (LME). Extremely malleable, which means it can be pressed into sheets, aluminum has many uses, particularly in making containers for food or other products.

To watch & read

1.10 mins from beginning 2. bring the trash back 3. exhausted metals

4. repair in developing countries 5. restart proj in europe 6. direct impact effort? 7. Catching the small fish 8. back to the gold

Blame Game documentary

Exporting Harm: The High-Tech Trashing of Asia

The Digital Dump: Exporting Re-use and Abuse to Africa

Urban mining documentary

Making and Breaking: Electronic waste recycling as methodology, Daniël Ploeger

article right to repair

Battery scavengers / A small practical exercise

During this short workshop we will make a smooth transition from talking about energy harvesting to the area of e-waste

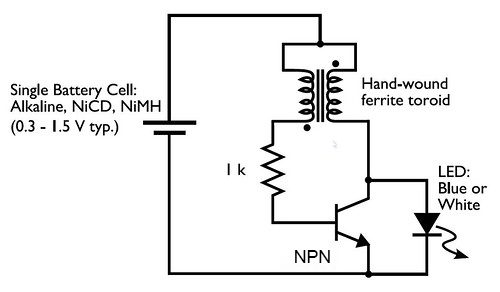

A Switch-Mode Power-Supply boost dc-to-dc Converter aka Joule Thief

https://en.wikipedia.org/wiki/Joule_thief

Here is how a basic Joule Thief works, step by step:

1. Initially the transistor is off.

2. A small amount of electricity goes through the resistor and the first coil to the base of the transistor. This partially opens up the collector-emitter channel. Electricity is now able to travel through the second coil and through the collector-emitter channel of the transistor.

3. The increasing amount of electricity through the second coil generates a magnetic field that induces a greater amount of electricity in the first coil.

4. The induced electricity in the first coil goes into the base of the transistor and opens up the collector-emitter channel even more. This lets even more electricity travel through the second coil and through the collector-emitter channel of the transistor.

5. Steps 3 and 4 repeat in a feedback loop until the base of the transistor is saturated and the collector-emitter channel is fully open. The electricity traveling through the second coil and through the transistor are now at a maximum. There is a lot of energy built up in the magnetic field of the second coil.

6. Since the electricity in the second coil is no longer increasing, it stops inducing electricity in the first coil. This causes less electricity to go into the base of the transistor.

7. With less electricity going into the base of the transistor, the collector-emitter channel begins to close. This allows less electricity to travel through the second coil.

8. A drop in the amount of electricity in the second coil induces a negative amount of electricity in the first coil. This causes even less electricity to go into the base of the transistor.

9. Steps 7 and 8 repeat in a feedback loop until there is almost no electricity going through the transistor.

10. Part of the energy that was stored in the magnetic field of the second coil has drained out. However there is still a lot of energy stored up. This energy needs to go somewhere. This causes the voltage at the output of the coil to spike.

11. The built up electricity can't go through the transistor, so it has to go through the load (usually an LED). The voltage at the output of the coil builds up until it reaches a voltage where is can go through the load and be dissipated.

12. The built up energy goes through the load in a big spike. Once the energy is dissipated, the circuit is effectively reset and starts the whole process all over again. In a typical Joule Thief circuit this process happens 50,000 times per second.

[description from here ]

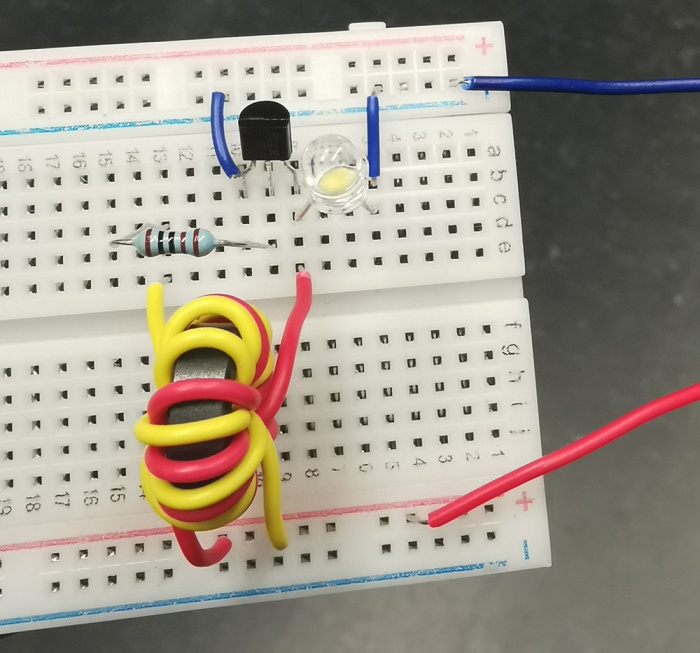

Winding the coil

Here we will find a nicely documented guide on the winding