Difference between revisions of "Using the CNC mill"

| Line 34: | Line 34: | ||

Here is an even longer [https://www.youtube.com/watch?v=qgx6MW8u2N8&t=3358s tutorial] including the finishing and soldering of a board<br> | Here is an even longer [https://www.youtube.com/watch?v=qgx6MW8u2N8&t=3358s tutorial] including the finishing and soldering of a board<br> | ||

| + | [https://fabacademy.org/2021/docs/tutorials/week06_electronic_design/eagle_english_workflow.html how to prep a file in eagle] | ||

===4. Milling the PCB=== | ===4. Milling the PCB=== | ||

[[File:Srm20.png|800px|center]] | [[File:Srm20.png|800px|center]] | ||

[[Category:Making]] | [[Category:Making]] | ||

[[Category:CNC Mill]] | [[Category:CNC Mill]] | ||

Revision as of 11:53, 22 September 2023

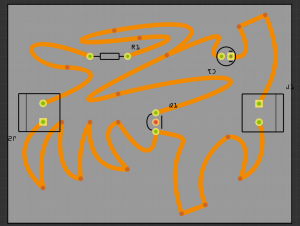

1. Designing the PCB

There are several ways for designing PCB. For example you can use the following softwares:

- Fritzing (easy to use) https://fritzing.org/

- Kicad (more professional) https://www.kicad.org/

Lets start with Fritzing.

That looks already quite good. After you finished the PCBs you have to export it as a "Extender Gerber (RS-274X)"-Format! Select the folder where you would like to save it.

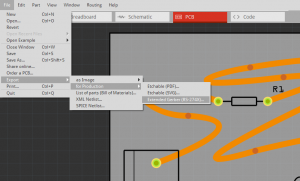

2. Generating the G-code

In this step you have to generate G-code with the Gerber files. G-code or sometimes called nc-code (numeric controll code) tells the CNC mill when to turn on the spindle or to which position it should move.

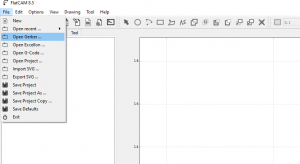

We will use FlatCam (http://flatcam.org/) to generate the G-Code.

- Start FlatCAM

- Click on [File] -> [Open Gerber ...]

- Select the ".gbl" (copper bottom) file

- Now select the file in the Project list and click on [selected]

settings flatcam:

- cut Z: -0.1 mm

- feedrate: 30 mm (is slow try 90)

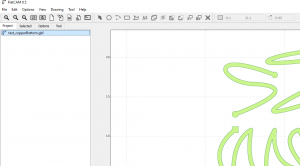

3. Using Mods

Alternatively we can use Mods (web based software from Fab Academy) to generate paths from .SVG or .PNG files

Mods project is a module based software with a web interface that already has a SRM-20 preset

Here is a good in depth tutorial how to use it but bare in mind that the interface has changed a bit and you may find differences

Here is an even longer tutorial including the finishing and soldering of a board