Difference between revisions of "Using the CNC mill"

Jump to navigation

Jump to search

| Line 16: | Line 16: | ||

* Start FlatCAM | * Start FlatCAM | ||

| − | * | + | [[File:Flatcam.png|thumb|center]] |

| + | * | ||

===3. Milling the PCB=== | ===3. Milling the PCB=== | ||

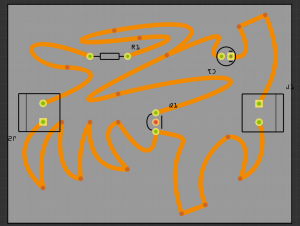

[[File:Srm20.png|800px|center]] | [[File:Srm20.png|800px|center]] | ||

[[Category:Making]] | [[Category:Making]] | ||

Revision as of 17:01, 3 November 2022

1. Designing the PCB

There are several ways for designing PCB. For example you can use the following softwares:

- Fritzing (easy to use) https://fritzing.org/

- Kicad (more professional) https://www.kicad.org/

Lets start with Fritzing.

That looks already quite good. After you finished the PCBs you have to export it as a "Extender Gerber (RS-274X)"-Format! Select the folder where you would like to save it.

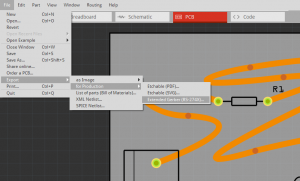

2. Generating the G-code

In this step you have to generate G-code with the Gerber files. G-code or sometimes called nc-code (numeric controll code) tells the CNC mill when to turn on the spindle or to which position it should move.

We will use FlatCam (http://flatcam.org/) to generate the G-Code.

- Start FlatCAM