Motors: Introduction and Types

DC Motors

DC (Direct Current) motors are two wire (power & ground), continuous rotation motors. When you supply power, a DC motor will start spinning until that power is removed. Most DC motors run at a high RPM (revolutions per minute).

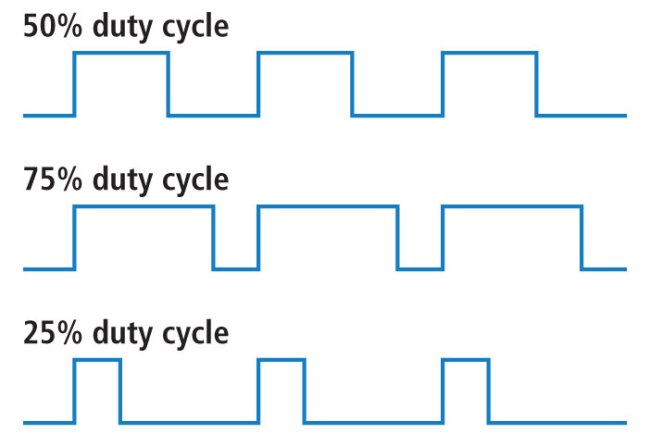

The speed of DC motors is controlled using pulse width modulation (PWM), a technique of rapidly pulsing the power on and off. The percentage of time spent cycling the on/off ratio determines the speed of the motor, e.g. if the power is cycled at 50% (half on, half off), then the motor will spin at half the speed of 100% (fully on). Each pulse is so rapid that the motor appears to be continuously spinning with no stuttering!

PWM examples of duty cycles

Servo motors

Servo motors are basically more flavoured Dc motors.

They are generally an assembly of four things: a DC motor, a gearing set, a control circuit and a position-sensor (usually a potentiometer).

The position of servo motors can be controlled more precisely than those of standard DC motors, and they usually have three wires (power, ground & control). Power to servo motors is constantly applied, with the servo control circuit regulating the draw to drive the motor.

Servo motors do not rotate freely like a standard DC motor. Instead the angle of rotation is limited to 180 Degrees back and forth. Servo motors receive a control signal that represents an output position and applies power to the DC motor until the shaft turns to the correct position, determined by the position sensor.

PWM is used for the control signal of servo motors. However, unlike DC motors it’s the duration of the positive pulse that determines the position, rather than speed, of the servo shaft. A neutral pulse value depending on the servo (usually around 1.5ms) keeps the servo shaft in the center position. Increasing that pulse value will make the servo turn clockwise, and a shorter pulse will turn the shaft anticlockwise. The servo control pulse is usually repeated every 20 milliseconds, essentially telling the servo where to go, even if that means remaining in the same position.

Inside

Internally, the mechanism of a servo motor uses a potentiometer attached to the rotating shaft to sense the position. It measures the width of the incoming pulse and applies current to the motor to turn the shaft, until the potentiometer indicates that the position corresponds to the incoming pulse width. This is a form of feedback control. The motor has received the desired position from the pulse width, and the actual shaft position is fed back to the circuit via the potentiometer. It compares the desired value to the actual value and drives the motor in the direction that causes actual to match desired.

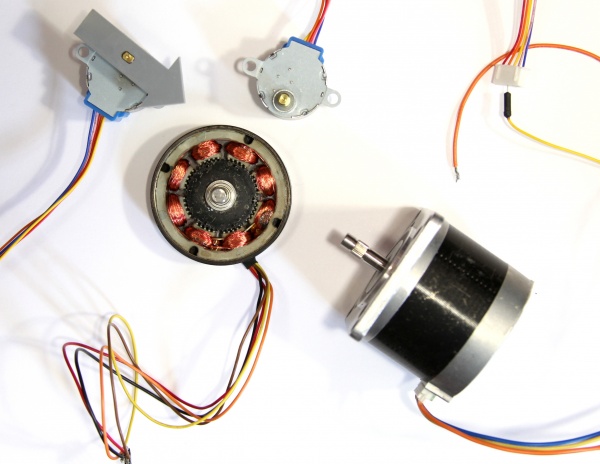

Stepper motors

A stepper motor is essentially a servo motor that uses a different method of motorization. Where a servo motor uses a continuous rotation DC motor and integrated controller circuit, stepper motors use multiple toothed electromagnets arranged around a central gear to define position.

Stepper motors require an external control circuit or micro controller (for instance a Raspberry Pi or Arduino) to individually energize each electromagnet and make the motor shaft turn. When electromagnet ‘A’ is powered it attracts the gear’s teeth and aligns them, slightly offset from the next electromagnet ‘B’. When ‘A’ is switch off, and ‘B’ switched on, the gear rotates slightly to align with ‘B’, and so on around the circle, with each electromagnet around the gear energizing and de-energizing in turn to create rotation. Each rotation from one electromagnet to the next is called a "step", and thus the motor can be turned by precise predefined step angles through a full 360 Degree rotation.

Stepper motors are available in two varieties; unipolar or bipolar. Bipolar motors are the strongest type of stepper motor and usually have four or eight leads. They have two sets of electromagnetic coils internally, and stepping is achieved by changing the direction of current within those coils. Unipolar motors, identifiable by having 5,6 or even 8 wires, also have two coils, but each one has a center tap. Unipolar motors can step without having to reverse the direction of current in the coils, making the electronics simpler. However, because the center tap is used to energize only half of each coil at a time they typically have less torque than bipolar.

The design of the stepper motor provides a constant holding torque without the need for the motor to be powered and, provided that the motor is used within its limits, positioning errors don't occur, since stepper motors have physically predefined stations.

Solenoids

Electric solenoids work on similar electromagnetic principles to those of DC motors, however, solenoids can use the magnetic energy to push or pull something rather than turn it. Solenoids are found in paintball guns, pinball machines, printers, valves and even automobiles.

A Solenoid is a coil that when energised, produces a controlled magnetic field down through its centre. By placing a magnetic armature inside that field, the armature can move in or out of the coil.

Extra Resources

Stepper motors, controlled via a micro controller are easy to follow at what rpm they operate, and to be adjusted AND with dc motors, it is a fixed rpm with a small torque, at which the motor operates, and in order to adjust this, gear systems, pulleys .....there is more.

Making things move is a book, very useful, please download it and look especially into Forces, Friction, and Torque (Oh My!) starting page 73 and then The Guts: Bearings, Couplers, Gears, Screws, and Springs page 189 till the end. But also check out the website for useful bits and pieces.

!!! WATCH THIS / very nice video from the Prelinger Archives, the motor part starts at 06:12

How to convert the motors movement into the desired one? Check out the Simple Mechanisms page.